Product

Manufacturing Method

Our main product are made by cold forge, hot forge and plus secondary operation.

Durabltec can produce the product depend on your requirement.

The manufacturing range is as follows.

Diameter : inch #1~5/8" / Metric M2~M16

Length : Inch 1/4" ~ 15" / Metric 5mm~400mm

The above range is popular used in the market, if your product is out of above range, we also can do it.

Main Products

① Electrical Part

Terminal screw and fasteners are used for electrical equipment.

② Auto production line Part

Appling in various area, such as Tapping ,thread forming ,plastic screw that are used for automotive assembly.

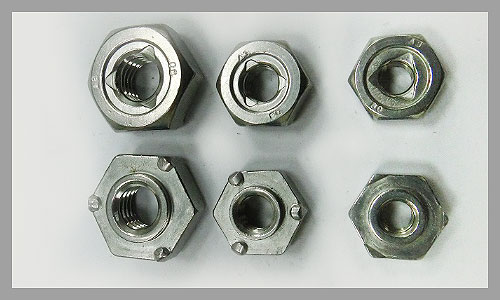

③ Prevented Lossing Fastener (BOLT&NUT)

To avoid lossen, ex. fasteners for vehicle.

④ Special Part

We can supply product according to the drawing and designed product.

If the part is used at automobile hibrid energy system, we also have experience can make it.

⑤ Turning Part

For precise part, will made by CNC.

⑥ For Indicated Material to develop screw & nut

Some materials (Steel,Plastic ,Wood,ACQ,MDF,WPC,Cement, Multi Layer board etc..)is developed for indicated area. Durable's fasteners can apply to building construction, window, furniture and house maintain.

⑦ Stamping part

Made by Transfer Processes, such as washer, clip etc.

⑧ Tooling of fastener

Accessories of mating fasteners, such as bit,holder, L key etc.